BBR VT CONA CME external post-tensioning system

The European approved CONA® CME post-tensioning system is the ultimate multi-strand technology for all types of externally post-tensioned applications. The standard tendon sizes range from 1 to 73 strands. CONA CME can be applied for the prestressing of bridges, precast segmental construction and repair and strengthening works of all kind of structures.

|

|

CONA CME tendons are situated outside the cross section of a structure. They can be made restressable and exchangeable for concrete and composite structures (steel, masonry and timber) and used in fully encapsulated as well as electrically isolated tendons.

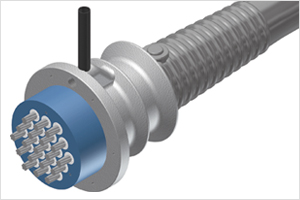

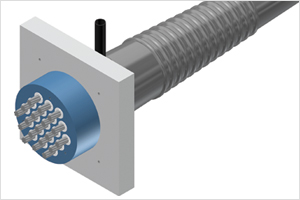

Anchorage configuration

The main components in the anchor zone of the CONA CME system are the wedges, anchor head, load transfer element and trumpet. For the load transfer to the concrete, the CONA CME BT (bearing trumplate) can be used for tendon sizes from 2 to 61 strands and the CONA CME SP (square plate) can be used for 1 to 73 strands. The CONA CME BT bearing trumplate system makes use of an advanced and proprietary three plane load transfer, allowing for very small centre and edge distances at the anchorages, as well as application of the full post-tensioning load at very low concrete strengths. The CONA CME SP square plate is a more traditional system with a single plane load transfer to the concrete.

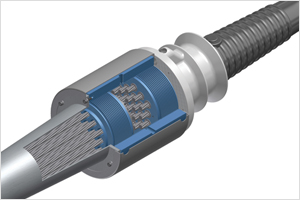

Fixed and stressable couplers

Although less common for external tendons, CONA CME tendons can be coupled using proprietary Type K overlap coupler for tendons ranging from 2 to 31 strands (larger sizes on request) or Type H sleeve coupler for 1 to 73 strands.

|

|

Deviator / saddle

An element that is specific to external prestressing is the deviator/saddle. The deviator transfers the transversal forces generated by the tendon to the structure and provides a smooth surface for the tendons. The deviator can be made of concrete, steel, HDPE or equivalent.

Corrosion protection

The strand bundle is enclosed in a smooth round plastic or steel duct. The filling of the tendons is carried out using a high performance BBR grout or grease/wax. It is also possible to use greased and HDPE sheathed monostrands in a grout filled duct offering multiple layers of corrosion protection. CONA CME post-tensioning kits can also be installed as fully electrically isolated tendons to provide the highest possible level of corrosion protection and inspectability.

CONA CME approvals

European Technical Approvals in different languages

See our Downloads page

CONA CME CAD drawings

CONA CMX

The Ultimate Design Guide Volume 2: System Specifications

See our Downloads page