BBR VT CONA CMI internal post-tensioning system

The European approved CONA® CMI internal bonded or unbonded post-tensioning system is internationally the most up-to-date and advanced multi-strand PT technology, ranging from 1 to 73 strands. It is typically used for bridges (both cast in-situ and precast), LNG/LPG storage, tanks & silos, nuclear power plants and stadiums.

|

|

CONA CMI can be made restressable and exchangeable for concrete and composite structures (steel, masonry and timber) and be used in fully encapsulated as well as electrically isolated tendons. Additionally CONA CMI can be used in both temporary and permanent cryogenic conditions as well as for nuclear applications. CONA CMI tendons also fulfill the requirements of AASHTO LRFD Bridge Construction Specifications including applications in special aggressive environments.

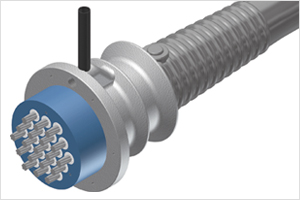

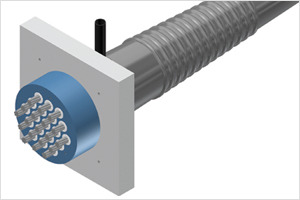

Anchorage configuration

The main components in the anchor zone of the CONA CMI system are the wedges, anchor head, load transfer element and trumpet. For the load transfer to the concrete, the CONA CMI BT (bearing trumplate) can be used for tendon sizes with 02 to 61 strands and the CONA CMI SP (square plate) can be used for 01 to 73 strands. The CONA CMI BT (bearing trumplate) system makes use of an advanced and proprietary three plane load transfer, allowing for very small centre and edge distances at the anchorages, as well as application of the full post-tensioning load at very low concrete strengths. The CONA CMI SP (square plate) is a more traditional system with a single plane load transfer to the concrete.

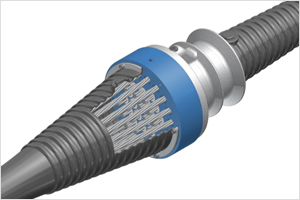

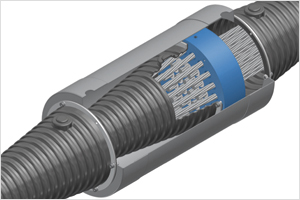

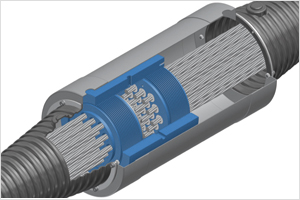

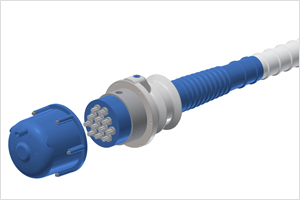

Fixed, stressable and movable couplers

CONA CMI tendons can be coupled using proprietary Type K overlap coupler for tendons ranging from 2 to 31 strands (larger sizes on request) or Type H sleeve coupler for 1 to 73 strands. Both coupler types can serve as a stressing / active anchorage coupler (Type S) or fixed / passive anchorage coupler (Type F) bearing against the load transfer unit or as movable couplers (Type B) along the length of the tendon.

|

|

|

|

Corrosion protection

The strand bundle is enclosed in a round or flat corrugated steel duct or BBR VT Plastic Duct. For special applications, such as loop tendons, smooth round steel ducts or BBR VT Plastic Ducts can be used. In bonded applications, tendons are filled with a high performance BBR grout. For unbonded applications, the duct can be injected with grease/wax or circulating dry air. It is also possible to use greased and HDPE sheathed monostrands in a grout filled duct offering multiple layers of corrosion protection. CONA CMI post-tensioning kits can also be installed as fully electrically isolated tendons to provide the highest possible level of corrosion protection and inspectability.

|

|

CONA CMI approvals

European Technical and additional approvals in different languages

See our Downloads page

CONA CMI CAD drawings

CONA CMX

The Ultimate Design Guide Volume 2: System Specifications

See our Downloads page